With volatility in material costs comes increased uncertainty about managing the supply chain. Analytics offers the potential to automatically combine data across operations and provide insights managers can use to contain costs and accurately predict future needs.

Bottom-Line Returns

Ensure costs are optimized in the short term and better predict changing costs into the future

Efficiency Gains

Improve process for blending data to fully understand total cost of materials

Risk Reduction

Reduce chance of excluding signals that indicate cost increases or volatility

Business Problem

As your supply chains grow in steps and complexity, how do you keep up with the data they generate at every step? Historical data is as important as current data, but even if you can access all of it, are you really able to use all of it to make decisions? And how do you factor in external data?

The goal of supply chain cost optimization is to reduce spend and maximize efficiency from vendor sources to the point of production. Most analysts, however, spend far more time finding, cleaning, and preparing data from multiple sources than using it. Stuck with spreadsheets as their go-to analysis tool, they manually blend vendor lists with product and pricing data into models that they regularly need to recreate.

Alteryx Solution

Through analytics and automation, companies introduce repeatability and accuracy to the process of optimizing supply chain costs. Workflows relieve the burdensome, error-prone process of pulling data from multiple sources into a model for making decisions on supplier standardization, conversion, and cost information. Low-code/no-code analytics enables analysts to build solutions quickly and get data into the hands of decision makers.

Automation accelerates the process of cleansing and prepping data and increases accuracy by eliminating manual steps. Advanced analytics allows companies to reap the benefits of lower costs along the supply chain, better inventory management, more efficient request-for-proposal processes, and better use of analysts’ time.

- Download the Alteryx Supply Chain Starter Kit to get started optimizing inventory or creating demand prediction models

- Automate connection to data sources along the supply chain, and inventory or demand model outputs, and automatically blend that data to create a full view of total operations costs

- Feed data into the Optimization Tool to fully optimize supply chain costs

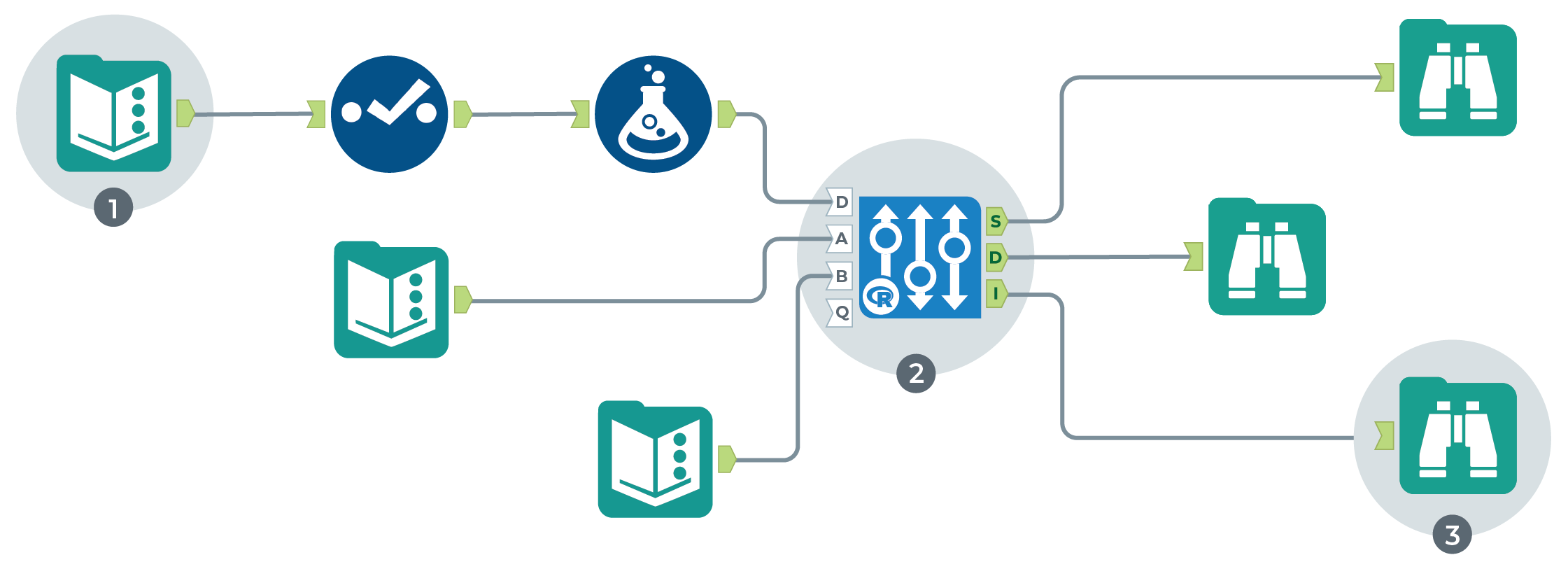

1 – Data Connection

Automatically connect to 80+ data sources all along the supply chain

2 – Optimization

Effortlessly connect outputs to dashboards, or operationalize models in procurement and operations plans

3 – Data Visualization

- Open rate is lower than 0.5%

- Segment is unlikely to justify time, effort, or expense